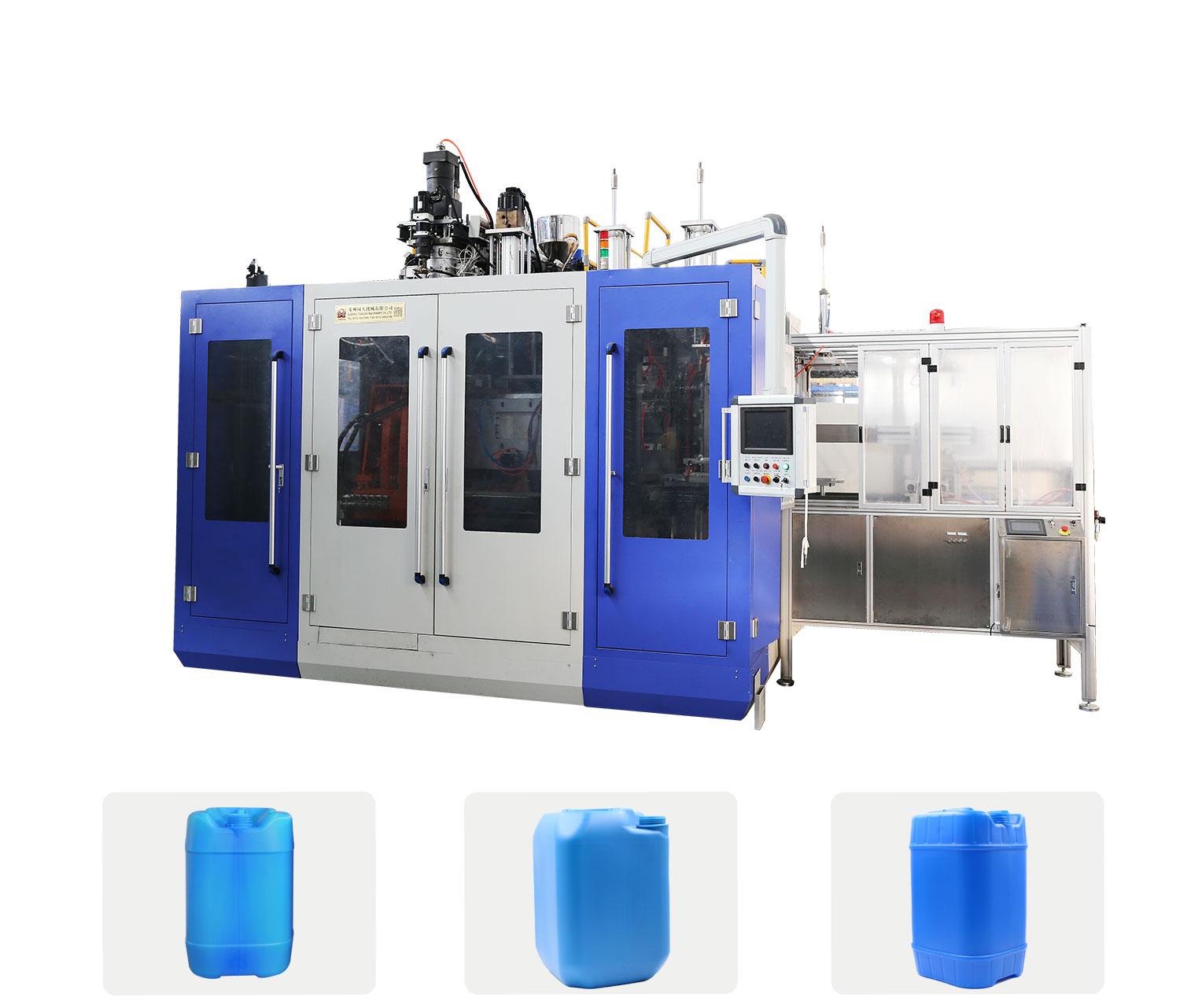

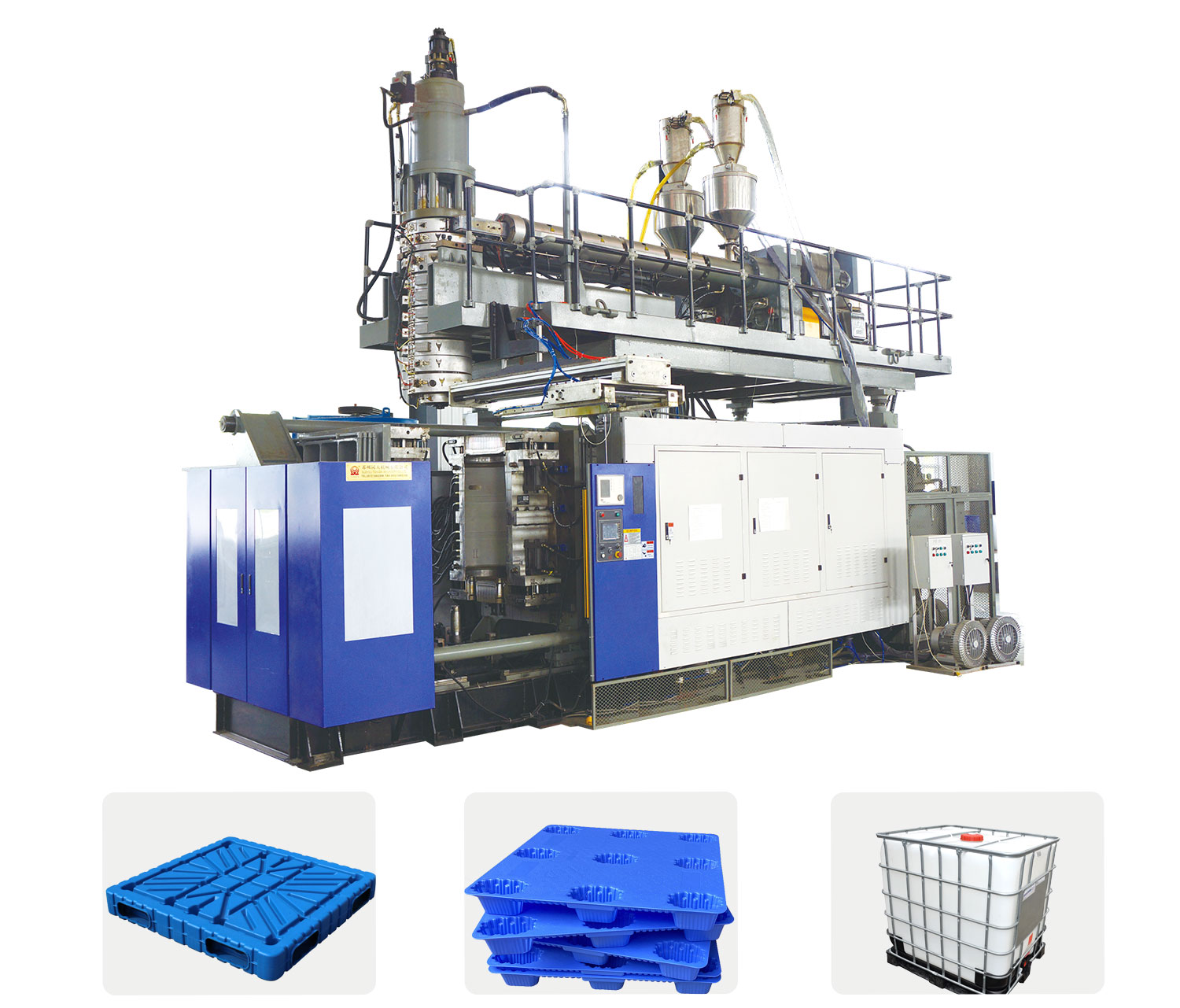

2L BLOW MOULDING MACHINE

Technical Features:

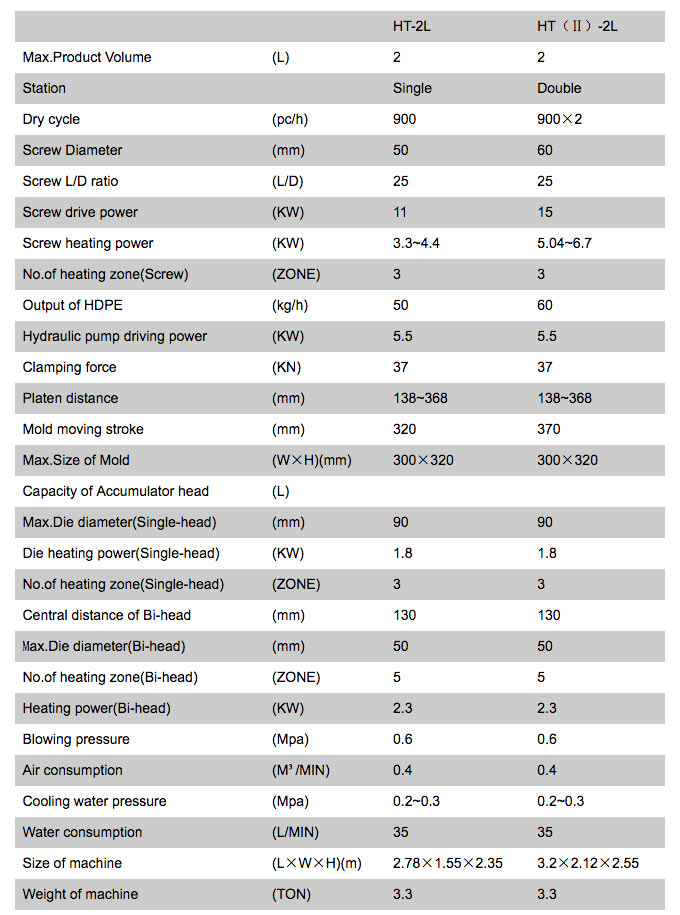

1, Electronic control system: Japanese Mitsubishi PLC computer plus man-machine interface (Chinese or English) red paper, touch-screen operation. All process settings, changes, search, monitoring, fault diagnosis and other functions are achieved on the touch screen, no contact with the working principle, components and durable.

2, Hydraulic system: proportional pressure control, equipped with imported brand-name hydraulic components, stable and reliable.

3, Plasticizing system: efficient plasticizing mixing screw, plastic plastic to ensure adequate and uniform.

4, Speed control system: frequency control + alloy steel gear reducer, smooth speed, low noise, durable

5, Opening and closing mode, mobile system: beam arm, three o’clock, the center of the mold clamping mode, to ensure long-term use. Clamping force balance, no deformation, and the use of translation mode body (ball linear guide), high precision, less resistance, faster.

6, Blowing needle holder: the overall angle-type blowing needle holder, stable and not shift, to ensure that products cut smooth