Blow molding machine classification

According to the process combination of the blow molding machine, the blow molding machine can be divided into three categories: extrusion blow molding machine, injection blow molding machine and special structure blow molding machine. Stretch blow molding machines can be assigned to each of the above categories.

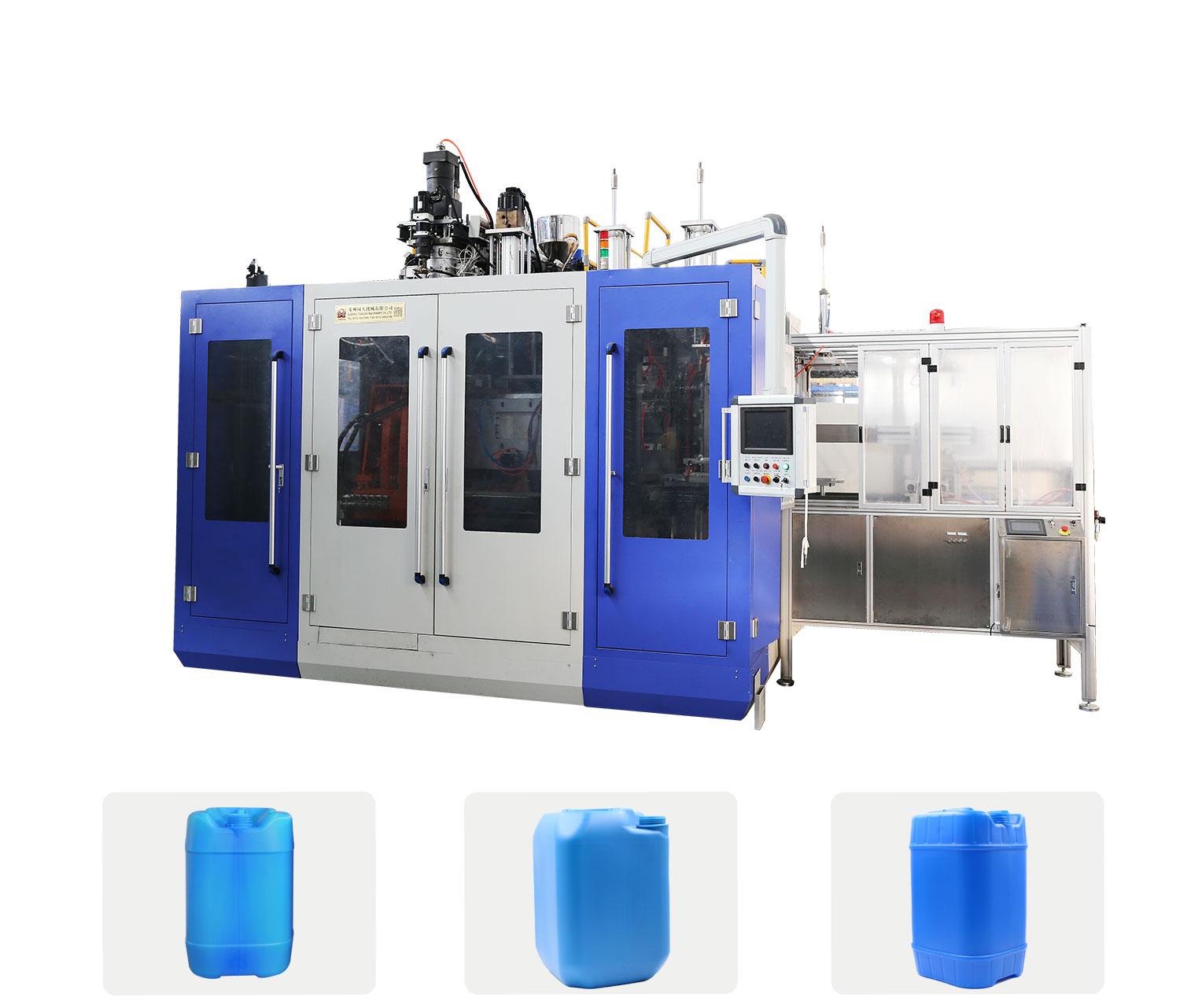

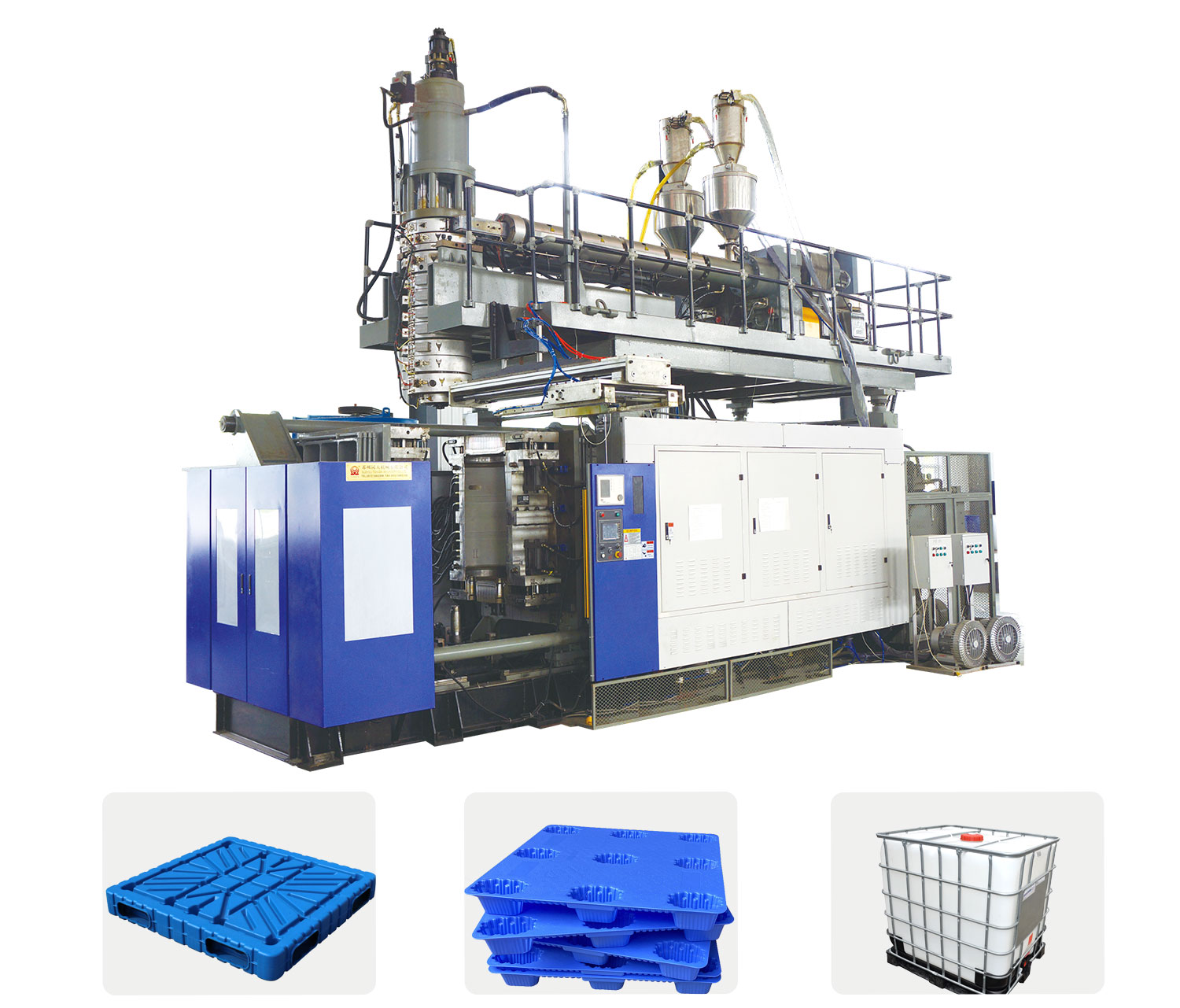

1) Extrusion blow molding machine

The extrusion blow molding machine is a combination of an extruder and a blow molding machine and a clamping mechanism, and is composed of an extruder and a parison die, an inflation device, a mold clamping mechanism, a parison thickness control system, and a transmission mechanism. The parison die is one of the important components that determine the quality of the blow molded article, usually with a side feed die and an intermediate feed die.

The storage cylinder type blank die is often used for blow molding of large products. The storage tank has a minimum volume of 1kg and a maximum capacity of 240kg. The parison thickness control device is used to control the parison wall thickness, and the control point is up to 128 points, generally 20 to 30 points. The extrusion blow molding machine can produce hollow products with a volume range of 2.5mL~104L.

2) Injection blow molding machine

The injection blow molding machine is a combination of an injection molding machine and a blow molding mechanism, including a plasticizing mechanism, a hydraulic system, a control device, and other mechanical components. Common types are three-position injection blow molding machines and four-station injection blow molding machines. The three-station machine has prefabricated parisons, inflating and demoulding three stations, each station being separated by 120°. The four-station machine has one more pre-forming station, and each station is separated by 90°. In addition, there is a two-station injection blow molding machine with 180° between stations. The plastic containers produced by injection blow molding machines are accurate in size and do not require secondary processing, but the mold costs are high.

3) Stretch blow molding machine

Stretch blow molding machines are commonly used to produce PET bottles and the like. Stretch blow molding machine generally consists of heating assembly, conveying assembly and blow molding assembly, with up to 16 mold stations (each station has a continuous output of 1200 / h ~ 1300 / h PET bottles, the basic output is 19200 /h~ 20800/h). The stretch blow molding machine can be operated clockwise or counterclockwise, greatly increasing the flexibility of the layout.