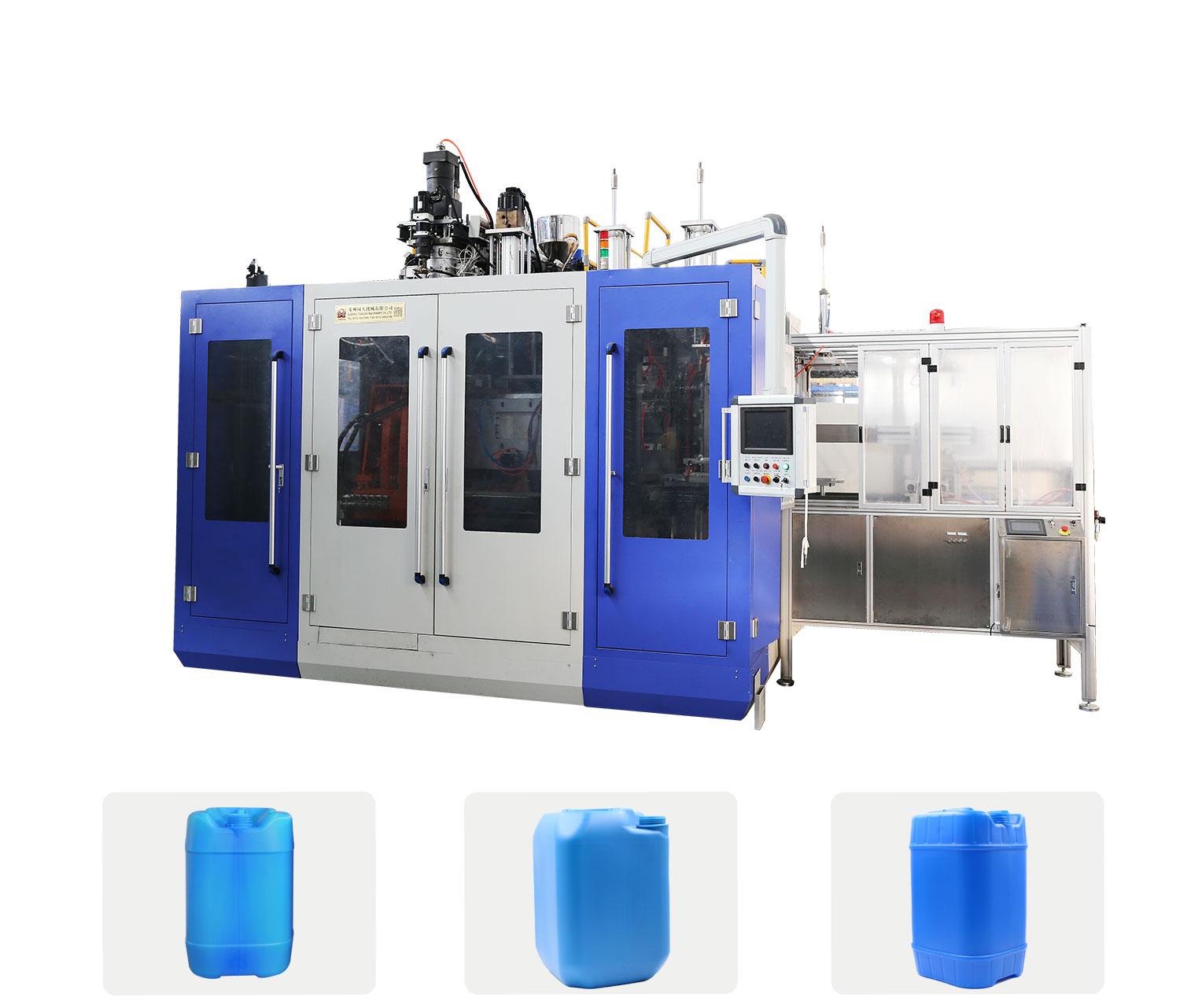

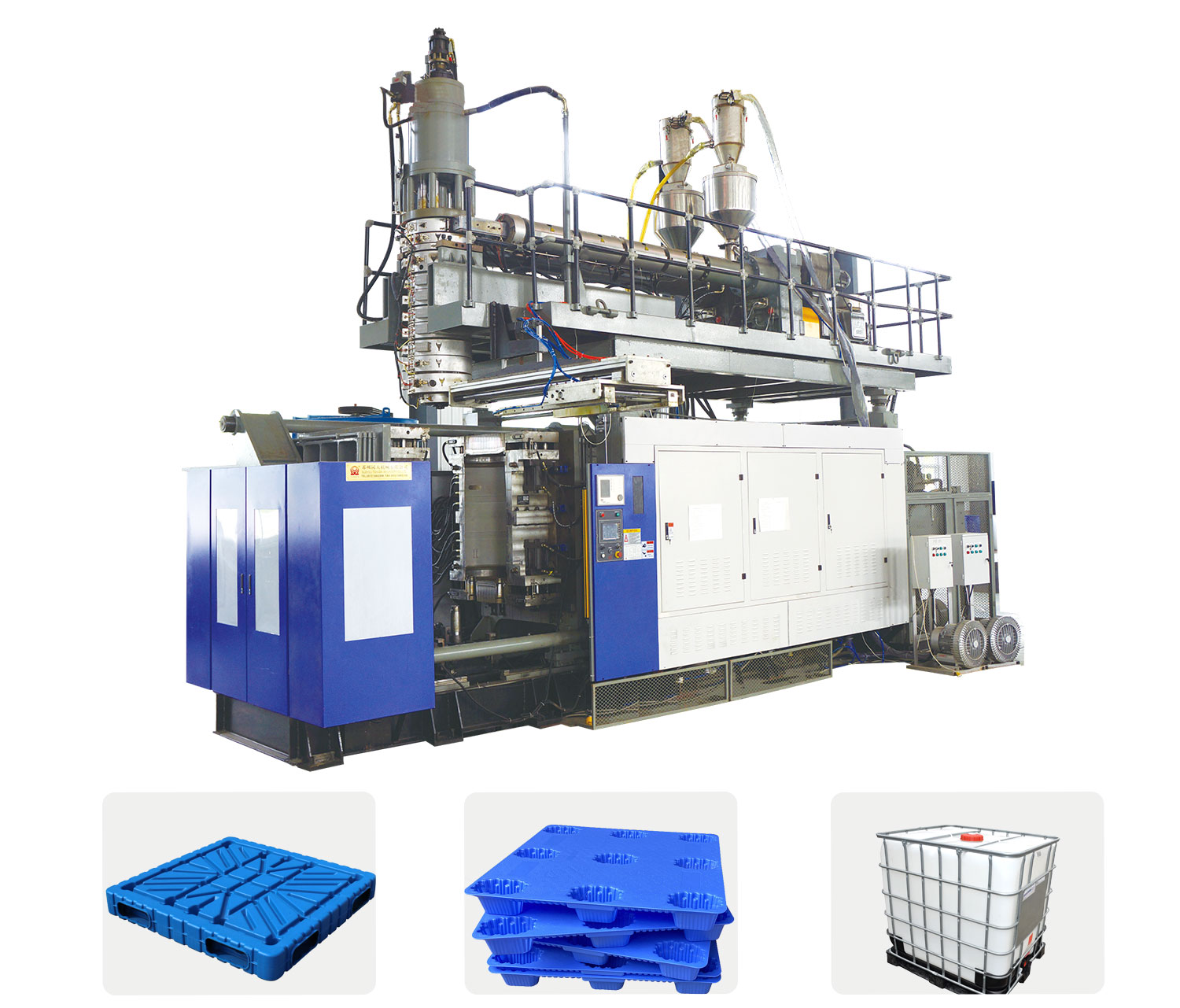

Examining rub-free packaging container production via extrusion blow molding technology

Hollow blow molding is to put the tube blank obtained by extrusion or injection molding into a mold, injecting compressed air into the tube blank to inflate it, and then adhering it to the cavity wall, and then cooling to release the hollow product. Forming method. This molding method can produce various packaging containers such as bottles, pots and barrels, daily necessities and children’s toys.

First, blow molding materials

Plastics used for hollow blow molding include polyethylene, polyvinyl chloride, polypropylene, polystyrene, linear polyester, polycarbonate, polyamide, cellulose acetate, and polyacetal resins. High-density polyethylene consumes the most, and is widely used in the packaging of food, chemical and process liquids. High molecular weight polyethylene is suitable for the manufacture of large fuel tanks and barrels. Polyvinyl chloride is widely used in the packaging of cosmetics and detergents because of its good transparency and air tightness. With the development of non-toxic polyvinyl chloride resins and auxiliaries, as well as the development of stretch blow molding technology, the use of polyvinyl chloride containers in food packaging has increased rapidly and has begun to be used in beer and other beverages containing carbon dioxide gas beverages. . Linear polyester materials are new materials that have entered the field of hollow blow molding in recent years. Due to its glossy appearance, excellent transparency, high mechanical strength and good preservation of the contents of the container, the waste incineration treatment does not pollute the environment, so the development of the bottle is very fast, especially It is the most widely used in pressure-resistant plastic food containers. Due to the improvement of its resin modification and processing technology, the use of polypropylene has also increased year by year.

Second, process classification and characteristics

Hollow blow molding technology

1. Different classification according to the tube blank forming method: extrusion-blow molding: the production method is simple, the output is high, the precision is low, and the application is more. Injection-blow molding: high precision, good quality, high price, suitable for large batch products.

2, according to the different molding process:

Ordinary blow molding

Stretch blow molding: The product is stretched, high strength and good air tightness. Extrusion-stretching-blow molding (referred to as extrusion-pull-blowing). Injection-stretching-blow molding (referred to as note-pull-blow).

3, according to the number of layers of the tube blank:

Single layer blow molding

Multi-layer blow molding: good overall performance, complex production, suitable for product packaging with high packaging requirements.

Third, the influencing factors

1 Blowing pressure: In blow molding, compressed air has two functions. One is to make the tube swell and close to the cavity wall to form the desired shape; the other is to cool. Depending on the type of plastic and the temperature of the parison, the air pressure is not the same, generally controlled between 0.2-0.7 MPa, and the most suitable is to make the product show clear pressure under the shape and pattern after molding. For lower viscosity, easy to deform lower values; higher values for plastics with higher viscosity and modulus; higher pressure for large volume and thin wall products; lower pressure for small volume and thick wall products .

2, inflation speed: in order to shorten the blowing time, in order to facilitate the product to obtain a more uniform thickness and a better surface, the inflation rate (the volume of air flowing per unit time) should be as large as possible, but not too large, otherwise Will cause adverse effects on the product: First, it will create a vacuum at the air inlet, so that this part of the parison is invaginated, and when the parison is fully inflated, the invagination part will form a diaphragm; secondly, the die part The parison may be pulled off by an extremely fast airflow, causing waste. To do this, it is necessary to increase the diameter of the blow pipe or to appropriately reduce the inflation speed.

3. Inflating ratio: The ratio of the size of the product to the size of the parison is usually referred to as the inflation ratio. When the size and weight of the parison are constant, the larger the size of the article, the larger the blow ratio of the parison. The size of the inflation ratio is determined according to the type and nature of the plastic, the shape and size of the product, and the size of the parison. The blow ratio is usually controlled at 2 or 4 times.

4, mold temperature and cooling time: In order to ensure the quality of the product, the temperature of the mold should be evenly distributed, the mold temperature is generally maintained at 20-50 ° C. If the mold temperature is too low, the elongation of the plastic at the jaws is lowered, the swelling is not easy, and the product is thickened in this portion, and the molding is difficult, and the outline and pattern of the product are not clear. The mold temperature is too high, the cooling time is extended, and the production cycle is lengthened. The product is deformed and the shrinkage is increased. The temperature of the mold depends on the type of plastic. When the glass transition temperature of the plastic is high, a higher mold temperature can be used; otherwise, the mold temperature is lowered as much as possible. The cooling time is generally extended as the wall thickness of the product increases. In addition to cooling the mold, the molded article may be internally cooled, that is, directly cooled into the interior of the product by introducing various cooling media (such as liquid nitrogen, carbon dioxide, etc.).

5. Molding cycle: The cycle of blow molding includes the process of extruding parison, cutting parison, clamping, blowing, cooling, venting, opening, and taking out products (subsequent finishing, matching, packaging, etc.).

Fourth, product features and applications

Hollow blow molding technology

LDPE: food packaging container

HDPE: commodity container

Ultra high molecular weight PE: large container, melt tank

PVC: mineral water, detergent bottles

PP: thin walled bottle

PET: beverage bottle